HDS-Sawmill Tools have always been designed for the requirements at the sawmill. The enhanced performance of such optimised sawmill tools combined with the satisfaction of our customers has now encouraged us to firmly anchor this optimisation process in our company philosophy and give it a uniform name.

“SoWa Sawmill Optimised Tool Design” puts our optimisation process in a nutshell.

We manufacture HDS circular saw blades, segments, knives and components for Baljer & Zembrod, Bruks, Carmanah Kadant, Costa Righi, EWD, Haas, Hombak, Holtec, Hundegger, Kallfass, Klöckner, Linck, Möhringer, Pallmann, Paul, Raimann, Rudnick & Enners, SAB, Söderhamn, Springer, USNR, Vecoplan and Veisto HewSaw machines, among others.

Technology

Technology

Our HDS “Sawmill tools” product range covers the majority of a modern sawmill’s tool needs.

For log yards there are our robust CROSSCUT circular saw blade with interchangeable inserts measuring up to 2.8 metres in diameter, and the tried and tested SPINCUT milling shaft butt end reducer.

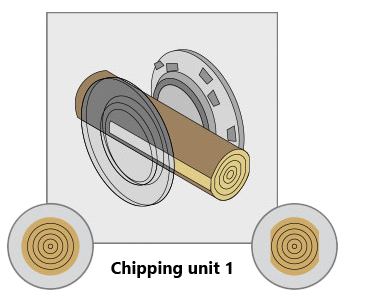

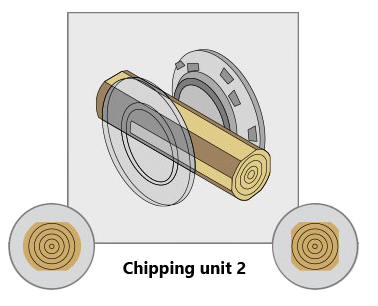

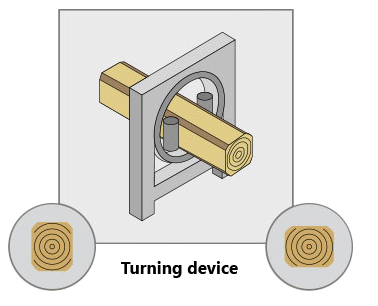

For chipping we can supply all the necessary sawmill tools for your units. Here our product range includes segments, sizing rings and knives of various design styles. For economic increase in performance we offer our CANTERCUT chipper canter, a complete and optimally coordinated tool solution.

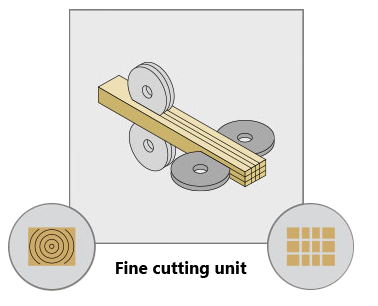

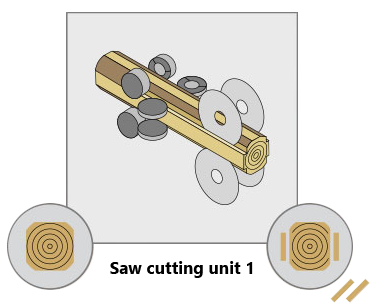

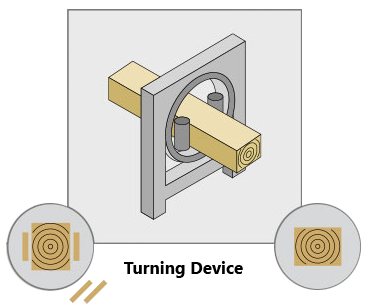

For profiler and cutting units, in addition to our complete PROFILCUT profiler cutters we also supply all sizing rings, smoothing segments, smoothing knives and the necessary system components such as segment carriers, knife holders, pressure plates, etc.

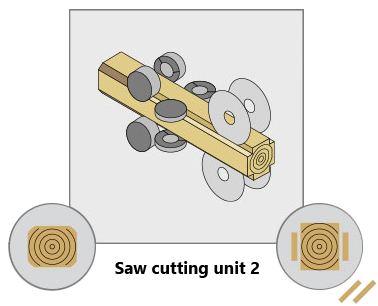

Our BASIC and the graduated STABILO provide two categories of high performance saw blades for all circular saw units. Both circular saw blades offer a number of technical refinements to coordinate optimally for the respective purpose.

HDS-Sawmill knives and the TRIMCUT circular saw blade designed specifically for trimming are used for subsequent processing.

- CANTERCUT chipper canter

- Sizing rings

- Smoothing segments

- Smoothing and chipping knives

- Knife holders, pressure plates

- Sizing ring carrier

- CANTERCUT chipper canter

- Sizing rings

- Smoothing segments

- Smoothing and chipping knives

- Knife holders, pressure plates

- Sizing ring carrier

- PROFILCUT profiler cutters

- Sizing ring/segment

- Profiler knife

- Knife holders, pressure plates

- Segment carrier

- STABILO circular saw blades

- BASIC circular saw blades

- Distance rings

- PROFILCUT profiler cutters

- Sizing ring/segment

- Profiler knife

- Knife holders, pressure plates

- Segment carrier

- STABILO circular saw blades

- BASIC circular saw blades

- Distance rings

- STABILO circular saw blades

- BASIC circular saw blades

- Distance rings